How Is a Vinyl Liner Made?

Sep 22nd 2025

What is a Vinyl Liner Pool Liner and Why It Matters

A vinyl pool liner is more than just a layer of material, it’s also what keeps the pool watertight, comfortable underfoot, and looking great for years. It lines the inside of the pool, forming a smooth and durable barrier along the pool base and structure.

Whether you’re building a new pool in your backyard or replacing your old liner, understanding how it's made can help you make the best choice for your pool. The quality of the liner and the processes used during manufacturing both factor into the longevity of the liner, how it fits, and how easy it is to maintain.

Step 1: Base Vinyl Material

Not all vinyl liners are created equal, and when it comes to your pool liner, the material used makes a big difference in how it holds up over time.

Vinyl liners start out as rolls of blank vinyl in a range of thicknesses. Most quality liners fall between 20-30 mils in thickness, making them thin enough to remain flexible but thick enough to resist tears.

The material is the entire foundation of the liner itself, it sets the stage for how your liner will perform in the years to come!

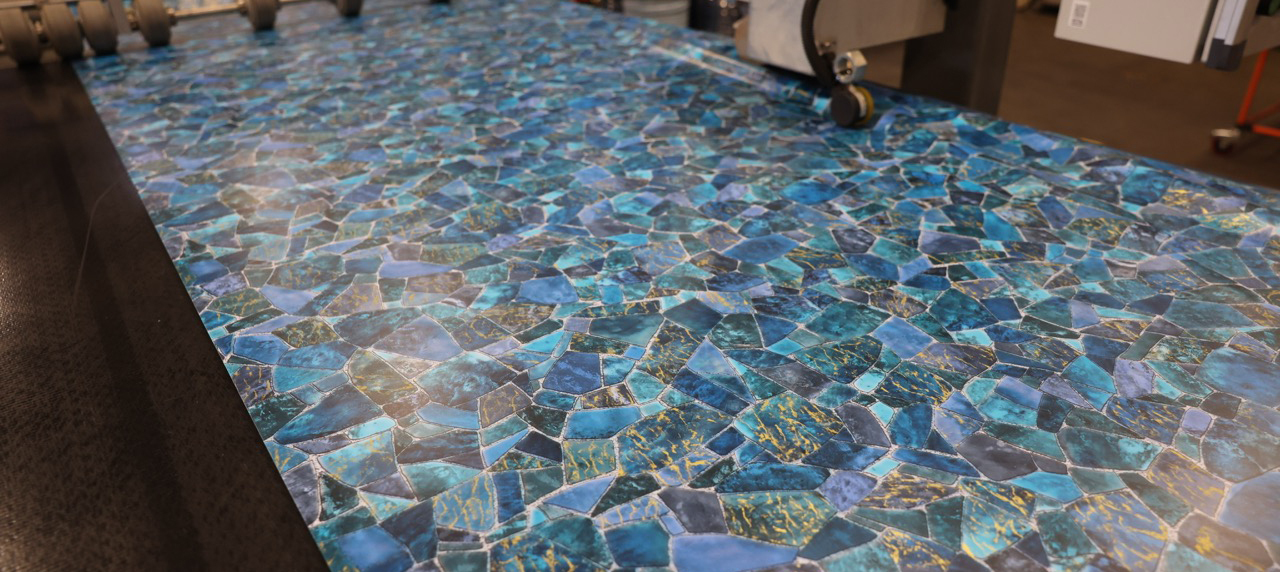

Step 2: Printing the Pattern

Once the raw vinyl material is selected, it’s time to give your vinyl liner its look. This is where design meets durability.

The base PVC is run through a large printer to apply the pattern. The ink and UV coatings used are formulated to bond with the vinyl and hold up against years of sunlight and pool chemicals.

The protective coatings used in this process seal the ink to prevent fading and add a protective barrier against abrasions, algae buildup, and chemical damage.

So, while the pattern might look like a design choice, it’s actually a carefully engineered step. It affects how your liner looks not just today, but years down the line.

Step 3: Custom Fitting

After the liner has been printed, the next step is all about fitting the film to your pool’s shape. No two pools are exactly the same, so it’s important to use precision when cutting the vinyl to make sure it matches the pool’s unique shape and size.

Using computer-aided design (CAD) and digital templates, manufacturers lay out the liner pieces to perfectly match the specs of your pool.

These templates account for:

- Pool depth and slope

- Curves, steps, and ledges

- Wall angles and corners

The goal is to make sure the liner fits like a glove, without too much stretch or sag once it’s installed. A poor fit can lead to wrinkles or premature wear.

Step 4: Welding the Seams

Once all the vinyl pieces have been cut, they need to be joined together to form one watertight, fitted liner. This is done through a process called welding.

Instead of stitching or gluing, welding uses direct heat or RF to fuse the vinyl pieces together. This creates a strong, watertight bond that won’t come apart under pressure or exposure to water or chemicals.

Stronger seams mean fewer chances of leaks, smoother joins to prevent wrinkles or raised edges, and clean seam lines to look and feel better underfoot.

Step 5: Final Inspection and Shipping

Before a vinyl liner makes it to your backyard, it goes through a detailed inspection process to make sure everything is just right.

Manufacturers check for:

- Seam integrity - Are all the welds solid and watertight?

- Correct dimensions - Does the liner match the exact specs of your pool?

- Surface quality - Are there any marks, bubbles, or flaws in the print or topcoat?

Some companies (like us!) also do leak testing or air inflation tests to ensure the liner holds its shape and seals properly.

Once it passes inspection, the liner is carefully folded, packaged, and shipped to be installed in your pool!

Why It All Matters: The Difference a Quality Liner Makes

From raw vinyl to a ready-to-install liner, every step in the process plays an important role in how your pool looks, feels, and holds up over time. Knowing what goes into a completed liner helps you choose a liner that’s not just beautiful - but built to last.

At Only Alpha Pool Products, we’ve spent decades perfecting pool liners that stand the test of time. Our liners are CFFA-certified, designed for durability, and available in a wide variety of patterns to fit your style.

View our Signature Series Liners Here

View our Exclusive Michelangelo Series Liners Here